Heat Seal Tester

Heat Seal Strength ASTM F2029

Heat seal tester is a laboratory instrument used to evaluate the sealing properties of packaging materials by measuring the strength, integrity, and quality of heat-sealed joints. It is commonly used in industries such as food packaging, pharmaceuticals, medical devices, and flexible packaging to ensure that heat-sealed products maintain their integrity during storage and transportation.

Heat sealing is a critical process in packaging, ensuring product safety and integrity. Heat seal tester evaluates the strength and quality of seals in flexible packaging materials. By following standardized procedures like ASTM F2029, manufacturers can optimize sealing conditions and ensure product reliability.

What is Heat Sealing?

Heat sealing is the process of bonding thermoplastic materials using controlled heat, pressure, and dwell time. This method is widely used in packaging industries to create airtight and tamper-proof seals, particularly in food, pharmaceutical, and medical applications.

Heat Seal Strength Testing

Heat seal strength refers to the force required to separate two sealed layers. Factors influencing seal strength include material composition, thickness, temperature, pressure, and dwell time. Evaluating heat seal strength ensures package integrity and prevents leakage or contamination.

Heat Seal Integrity Testing

Heat seal integrity testing verifies that seals remain intact under stress conditions such as pressure, temperature variations, and mechanical forces. Methods include visual inspections, bubble emission tests, and peel strength assessments to ensure compliance with industry standards.

Heat Seal Strength Test Method

The heat seal strength test method, as outlined in ASTM F2029, involves creating laboratory heat seals under controlled conditions. The key parameters include:

- Temperature: Set based on material properties and testing objectives.

- Dwell Time: The duration of heat application, affecting bond strength.

- Sealing Pressure: Typically between 0.15 to 0.7 MPa, ensuring optimal adhesion.

- Jaw Configuration: Jaws should be parallel, with suitable coverings to prevent material sticking.

The sealed specimens undergo strength testing using peel or tensile tests per ASTM F88 to determine force-to-failure and failure modes.

ASTM F2029 - Standard Practices for Heat Sealability Testing

ASTM F2029 provides guidelines for laboratory heat seal testing of flexible barrier materials. The key points include:

- Material Evaluation: Measures how different material properties impact heat sealability.

- Heat Seal Curve Analysis: Determines optimal sealing conditions by varying temperature in 5-10°C intervals.

- Specimen Preparation: Ensures consistent sample orientation and sealing conditions.

- Seal Strength Measurement: Uses peel testing to assess the bond’s durability.

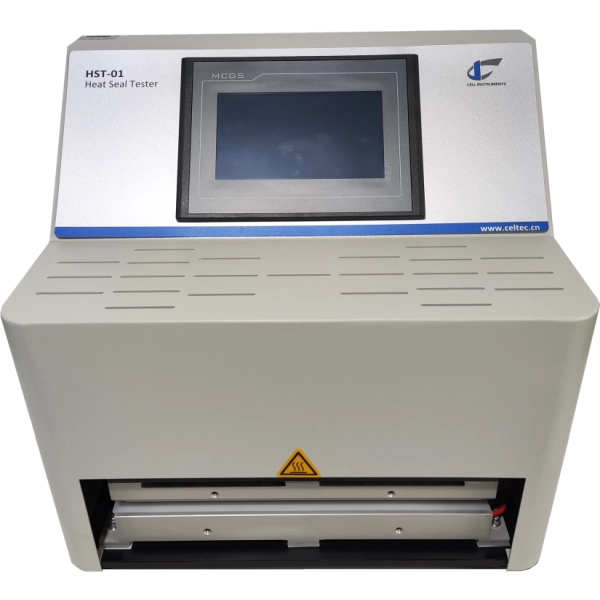

Heat Seal Tester - Advanced Technology for Precision Sealing

The HST-01 Heat Seal Tester is designed for superior sealing performance with high stability and precision. It features:

- PLC-controlled operation for industrial-grade reliability, with an HMI touch screen for easy use.

- Aluminum upper and lower heated components, ensuring minimal heat loss and stable temperature control.

- High-precision P.I.D. temperature controller for accurate and consistent heating.

- Synchronized seal initiation using an accurate proximity sensor.

- Three-direction guided sealing bar, ensuring uniform pressure for consistent results.

- User safety measures, including an anti-scald front cover and manual or foot-switch operation.

- Customizable seal jaws with varied dimensions, shapes, and patterns.

- Optional RS 232 COM port for data transfer and software integration.

Main Parameters

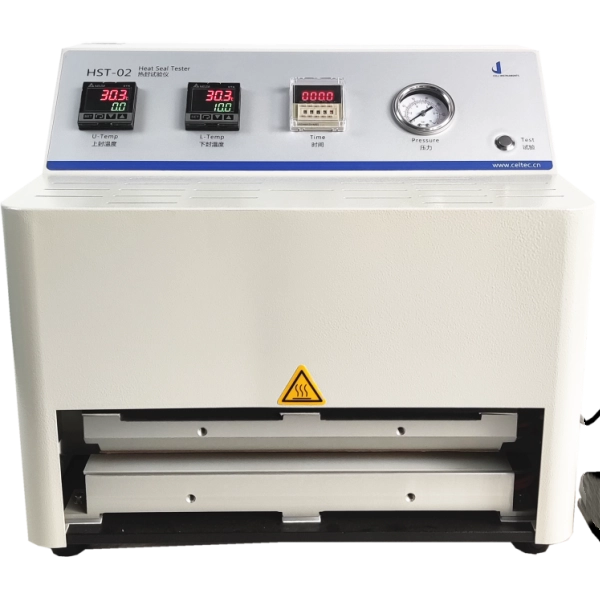

| Parameter | HST-01 Heat Seal Tester | HST-02 Heat Seal Tester | GHS-01 Gradient Heat Seal Tester | GHS-02 Gradient Heat Seal Tester |

| Sealing Temperature | Ambient ~ 300°C | Ambient ~ 300°C | Ambient ~ 250°C | Ambient ~ 250°C |

| Temperature Deviation | ±0.2°C | ±0.2°C | ±0.2°C | ±0.2°C |

| Sealing Time | 0.1S ~ 9999S | 0.1S ~ 9999H | 0.1S ~ 9999H | 0.1S ~ 9999H |

| Sealing Pressure | 0.15 ~ 0.7 MPa | 0.15 ~ 0.7 MPa | 0.15 ~ 0.7 MPa | 0.15 ~ 0.7 MPa |

| Seal Jaw Size | 330 × 10 mm | 330 × 10 mm | U: 40 × 10 mm (5 pcs), L: 330 mm (1 pc) | U: 40 × 10 mm (5 pcs), L: 330 mm (1 pc) |

| Gas Pressure Requirement | 0.7 MPa | 0.7 MPa | 0.7 MPa | 0.7 MPa |

| Port Size | Ф6 mm PU Hose | Ф6 mm PU Hose | Ф6 mm Pipe | Ф6 mm Pipe |

| Power Supply | AC 220V 50Hz | AC 220V 50Hz | AC 220V 50Hz | AC 220V 50Hz |

Test Process Using Heat Seal Tester

- Sample Placement: Position the flexible material sample between the upper and lower sealing jaws.

- Temperature Equilibrium: Allow the heating elements to stabilize at the set temperature.

- Sealing Action: The upper sealing jaw, driven by a gas cylinder, presses down with a controlled force.

- Dwell Time Control: The sample remains under pressure for the preset time.

- Completion: After the sealing time ends, the upper jaw returns to its original position, completing the process.

- Seal Strength Evaluation: The sealed sample is tested for integrity and durability following ASTM F2029 guidelines.

Importance of Heat Seal Testing in Quality Control

Industries such as food, pharmaceuticals, and medical packaging rely on heat seal testers to ensure:

- Leak-proof seals for extended shelf life.

- Regulatory compliance with packaging standards.

- Process optimization by identifying ideal sealing conditions.

- Reduced material waste through precise heat seal analysis.